"Eye of Wisdom" - Machine Vision Empowers the Application Development of the Drone Industry

The emergence of drones has injected fresh vitality into the development of various fields and industries. In recent years, technological research and development around UAVs abound, and the exploration of the application of machine vision in UAVs is one of the important directions.

Machine Vision System

Machine vision systems use machines instead of human eyes to make various measurements and judgments. The image is captured through machine vision products (i.e., image capture devices, such as CMOS and CCD, etc.), and then the image is transmitted to the processing unit. Through digital processing, the size, shape, and Judgment of color, etc.

Composition of Machine Vision System

Image acquisition unit: It is mainly composed of light source, lens, camera, image acquisition card and other hardware to convert the detection target into image signal.

Image processing unit: It mainly analyzes the collected images through image processing software to obtain detection results such as the size, position, angle, and number of the measured targets.

Output communication unit: mainly outputs the results obtained by the image processing unit through the communication interface to other actuators controlled by the robot or PLC to complete the action logic that needs to be executed.

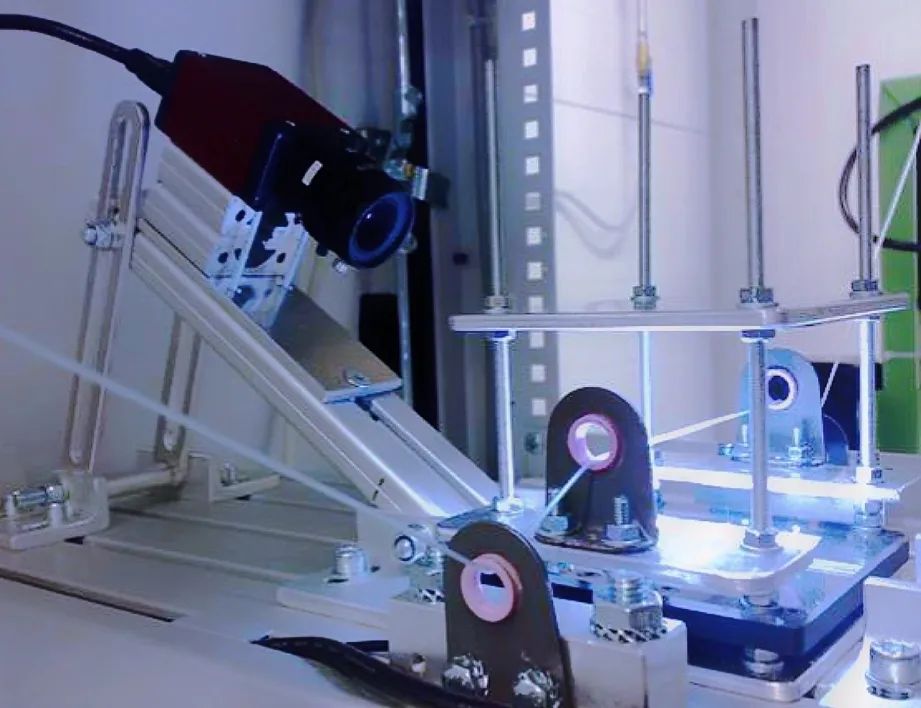

PC type (board type) machine vision system

A visual system based on a personal computer (PC), generally consists of a light source, optical lens, CCD or CMOS camera, image acquisition card, image processing software and a PC, which can realize relatively complex system functions.

Embedded machine vision system

It is easy to learn, use, maintain and install, and can build a reliable and effective machine vision system in a short period of time. Embedded machine vision systems can be divided into two categories: visual sensors and smart cameras according to product type.

Identify

In identification applications, machine vision systems perform identification by reading QR codes, component identification codes, component labels, etc., and can also identify components by locating unique patterns, colors, shapes, etc.

Machine vision system recognition

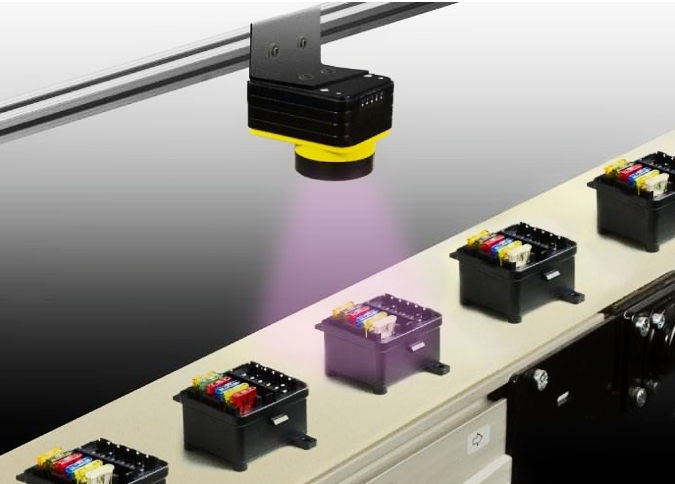

Detection

In inspection applications, machine vision systems confirm whether products meet quality requirements by detecting defects, contaminants, functional flaws and other non-compliances.

Machine vision system inspection

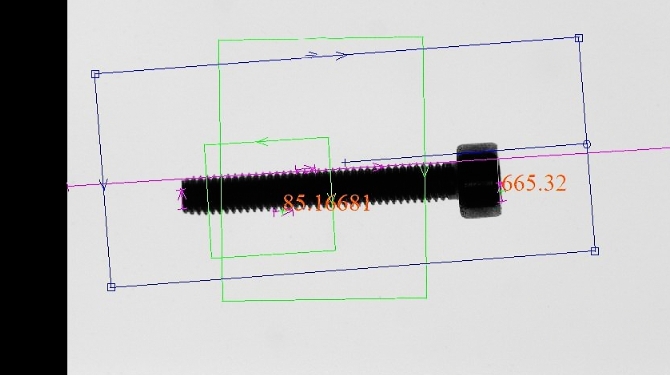

Measurement

In metrology applications, machine vision systems make measurements by calculating the distance between the geometric locations of objects being measured and then determining whether these measurements meet specifications.

Machine vision system measurement

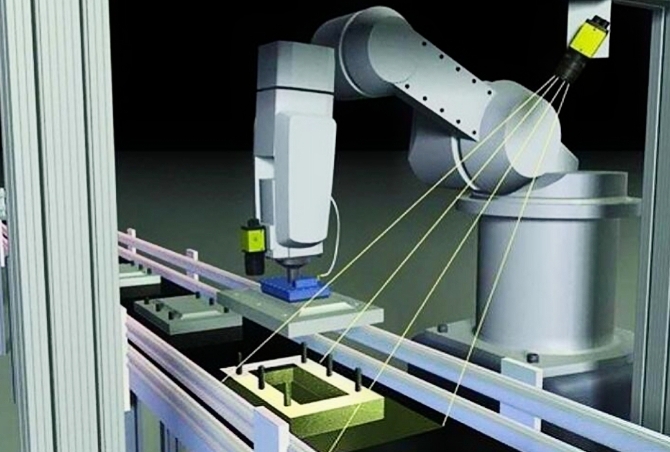

Positioning and Guidance

In machine vision applications, whether it is simple assembly inspection or complex 3D robot applications, pattern matching technology is required to locate target items or features within the camera's field of view. Machine vision systems can locate and report the position and orientation of components.

Machine vision system positioning

As an image capture and processing technology, machine vision can be combined with drones to obtain more high-altitude image information. This information is important for the application of drones in agriculture, surveying and mapping, security, inspection and other fields. of great significance.

Although the currently widely used drone aerial photography technology can obtain image information, it lacks control and cannot transmit images in real time. The machine vision system can build an image processing system to connect the drone and the control device, and achieve real-time reception and processing of image information by installing image sensing equipment.

The development of machine vision technology has brought a lot of room for development of drones. As the functions of drones continue to be enriched, they will help people complete more tasks that were difficult to complete in the past.

- Reinforcement Learning Enables Bipedal Robot to Conquer Challenging Terrain

- Drones for 3D Indoor Exploration-Cultural Relics Protection and Indoor Survey

- Industry Application: Intelligent Unmanned Operation Solutions for Lakes – Rapid Deployment for Continuous Protection

- High-Altitude Cleaning Case Introduction - Drone Spraying and Cleaning

- New Performance: SLAM Handheld Lidar Scanner + External Panoramic Camera New Combination