A Look at the Fuel Cell System "Performance Warrior"

This year marks the third year of my country's hydrogen fuel cell demonstration development. On the one hand, fuel cell companies are busy exploring the terminal market and expanding their capital reserves. On the other hand, under environmental uncertainty and survival pressure, companies are still continuing to hone their product basics in response to market demand, and optimizing and iterating technology around reliability, stability, life, hydrogen consumption and other performance.

This means that the industry has a clearer answer to the core question of "What is a good fuel cell system?" The fuel cell system is answering this question with practical actions. Focusing on the two main scenarios of automotive and power generation, Dr. Hou Junbo led the technical team to optimize the design and process iteration of core indicators such as system stability, reliability, hydrogen consumption, failure rate, and life, and delivered two excellent works of craftsmanship to the industry: automotive engine system and hydrogen energy storage power generation system.

High stability and low hydrogen consumption, the automotive fuel cell system has outstanding performance

In the automotive field, we have completed the development of a series of fuel cell engine systems with a power range of 30kW~235kW, which can be widely used in many vehicles such as passenger cars, city buses, light, medium and heavy trucks, forklifts, trailers, construction machinery, etc.

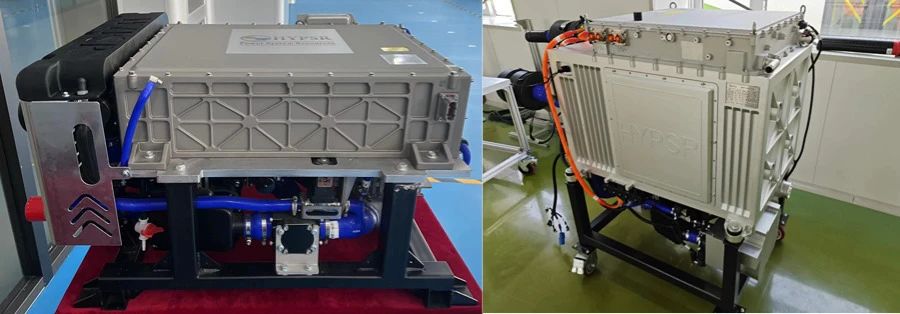

Automotive fuel cell engine products (70 kW on the left, 235 kW on the right)

Among them, 17 hydrogen fuel cell buses equipped with HYPSR-04 model 70KW on-board systems have recently delivered impressive operating data: These 17 buses have been running continuously for nearly a year and a half in Jiashan County, Jiaxing City, Zhejiang Province, with a total mileage of 800,000 kilometers, and an average hydrogen consumption of 3.7kg/100km, which is far lower than the industry average of 5kg/100km, showing significant advantages in helping Jiashan City's public transportation energy-saving and environmental protection transformation.

Jiashan County Bus

In addition to the purchase cost, the energy consumption per 100 kilometers is one of the most important economic indicators of the vehicle. In order to achieve commercialization of fuel cell vehicles, in addition to continuously promoting cost reduction in all links, it is very important to reduce the use cost of the vehicle during operation and reduce hydrogen consumption to improve fuel economy. The operating data of low hydrogen consumption proves its deep technical foundation in the fuel cell system and vehicle power matching.

In addition, the low failure rate is another highlight of this batch of buses in actual operation. The 70KW hydrogen fuel cell system not only meets the needs of daily bus operations, but also can provide stable and efficient power output under long-term and high-frequency use, without significant failures, which verifies its adaptability under complex road conditions and changing climate conditions.

"The total mileage is 800,000 kilometers, and the average consumption is only 3.7kg/100 kilometers. The smooth operation in various environments is the best proof of the reliability and practicality of our hydrogen fuel cell technology, and also demonstrates the huge potential of hydrogen fuel cell technology. The application of hydrogen fuel cells has a far-reaching impact on Jiashan City and the entire public transportation industry, and also provides an important reference for more cities to adopt clean energy buses."

New energy vehicles always encounter questions about stability and reliability in the early stages of development, and hydrogen fuel cell vehicles are no exception. Each batch of vehicles launched by fuel cell companies faces not only market performance tests, but also the trust of local governments and operators in fuel cell companies and even the entire industry.

In order to make products that the market can trust and ensure the stability and durability of the automotive fuel cell system, Liyuan Technology has devoted extraordinary efforts and wisdom in system architecture design, fault diagnosis mechanism, and operation status monitoring, ensuring that every link is refined, using the power of science and technology to build the foundation of quality, and making safety and reliability a distinctive label of the product.

"We have built a fault diagnosis framework in the engine control system, which can quickly diagnose the main fault types such as abnormal air path pressure, excessive hydrogen-air pressure difference, abnormal hydrogen pressure, low coolant circuit pressure, high coolant temperature, and drain valve jamming. We also set up a protective response mechanism for faults that may cause serious consequences to avoid damage to the stack as much as possible." Dr. Hou Junbo pointed out.

At the same time, each on-board fuel cell system is integrated with TBOX (see the figure below), which can monitor and warn the control system in real time for some performance degradations with a longer time scale, and has corresponding fault recovery strategies. The real-time data upload system based on TBOX can remotely monitor the operating status of the fuel cell engine system and realize remote fault troubleshooting. At the same time, the ever-expanding operating data set can be used to analyze, learn and mine the fault information contained therein, and continuously improve the data-driven intelligent diagnosis mechanism.

TBOX remote terminal monitoring system

There is no doubt that with the high stability, low hydrogen consumption, and durable fuel cell system characteristics, this fuel cell "newcomer" has opened the door to the trillion-level hydrogen vehicle market.

100kW-100MW, fixed power generation system has "four surprises"

In addition to automotive applications, fixed power generation applications are also one of the application scenarios that continue to be cultivated. GGII predicts that by 2030, the cumulative installed capacity of domestic fuel cell energy storage power generation is expected to reach 5GW, and the incremental market space for fuel cell power generation systems from 2023 to 2030 will exceed 24 billion yuan.

Focusing on the four key performances of modularization, intelligence, stability and durability, and reliability, fixed power generation systems have already come to the hydrogen energy storage market.

The rated power of the cabinet power generation module is 100kW, and the output is 380V AC; the rated power of the container module is 1MW, and the output is 10kV AC.

Cabinet-type power generation module (left), container-type power generation module (right)

The power generation module can operate independently and support multi-module parallel expansion. Combined with transformer equipment and energy storage units, it can flexibly realize the deployment of distributed power generation elastic capacity from 100kW to 100MW. It has the characteristics of standardized production, integrated transportation, and simple on-site construction.

Second, each power generation module product has independent self-consistent control functions, which ensures the intelligence of the entire power generation system to achieve the purpose of reducing hydrogen consumption and attenuation.

The container-type module has four fuel cell systems built in. The microgrid controller receives external commands and sends control signals to each fuel cell system and inverter. When multiple modules are operated in parallel, the operating data of each fuel cell system penetrates the module level and is connected to the comprehensive intelligent energy management system at high speed and in real time to achieve cloud-based centralized scheduling and remote operation and maintenance.

The intelligent energy management system can optimize the output power of each fuel cell in real time at the stack level, improve the average efficiency of each stack, reduce the total hydrogen consumption of the system, and take into account the constraint of power fluctuation rate to delay the attenuation of stack performance. At the system level, the energy management system has the function of self-adapting the power consumption mode, which can automatically match the optimal power generation mode according to the power consumption characteristics to avoid frequent start-stop, frequent load changes and other high-loss conditions.

Third, fixed power generation applications have extremely high requirements for the stability and durability of fuel cell products. Liyuan Technology has made optimizations from the material, component to system level. For example, through the selection of key raw materials such as PEM, GDL, catalyst, and structural optimization of MEA, the membrane electrode R&D team has developed a membrane electrode with a four-layer frame structure, which can provide the long-lasting MEA required for fixed power stations; by optimizing the system's response strategies under start-stop, variable load, high/low load and other working conditions, the loss of materials such as proton exchange membrane, catalyst, gas diffusion layer, etc. is avoided, and the life of the stack is extended.

Fourth, at the system design and control level, a variety of methods are used in combination to improve the reliability of the fuel cell stack.

A coordinated control method for the air compressor and back pressure valve was developed for the air supply system, which can achieve the decoupling of air flow and intake pressure, so that the two can respond to system requirements quickly and accurately, and can still maintain strong robustness when the working conditions and environmental conditions change greatly, effectively avoiding damage to the stack due to insufficient air supply under variable load conditions.

A method of hydrogen ejector proportional valve feedforward + adaptive closed-loop control was developed for the hydrogen circulation system, which accurately matches the moment of hydrogen discharge valve opening and proportional valve opening change, and can effectively suppress the pressure fluctuation on both sides of the membrane electrode caused by the opening of the hydrogen discharge valve, greatly reducing the risk of membrane electrode perforation.

A state observer was designed for the membrane water content, which estimates the liquid water content on the anode and cathode sides of the stack based on the anode hydrogen flow estimation and the cathode stack inlet and outlet pressure difference, and controls the membrane water content in real time within a reasonable range by adjusting the hydrogen discharge valve opening time and the air excess ratio, effectively reducing the frequency of membrane dry and flooding failures.

"Our fuel cell power generation system can be truly stable and reliable, and is suitable for fixed power stations of various sizes." Liyuan Technology concluded.

It is understood that in the zero-carbon smart energy demonstration project in the company's factory area, the power station project using water electrolysis to produce hydrogen + fuel cell power generation technology is operating stably, with an electricity-hydrogen-electricity conversion efficiency of 35%, which is an obvious efficiency advantage in the industry.

In terms of the industry, hydrogen energy storage, as a representative of long-term energy storage technology, has been included in the official support for new energy storage. With the reduction of hydrogen production and storage and transportation costs, distributed power generation devices are expected to be promoted.

Although the application of fuel cell power generation is still in its early stages of development and faces many difficulties and challenges that need to be overcome, as a pioneer in the industry, it has deeply explored application scenarios with a forward-looking vision and firm steps, and overcome technical difficulties one by one, paving a solid path for the development of fuel cell power generation applications.

- Reinforcement Learning Enables Bipedal Robot to Conquer Challenging Terrain

- Drones for 3D Indoor Exploration-Cultural Relics Protection and Indoor Survey

- Industry Application: Intelligent Unmanned Operation Solutions for Lakes – Rapid Deployment for Continuous Protection

- High-Altitude Cleaning Case Introduction - Drone Spraying and Cleaning

- New Performance: SLAM Handheld Lidar Scanner + External Panoramic Camera New Combination